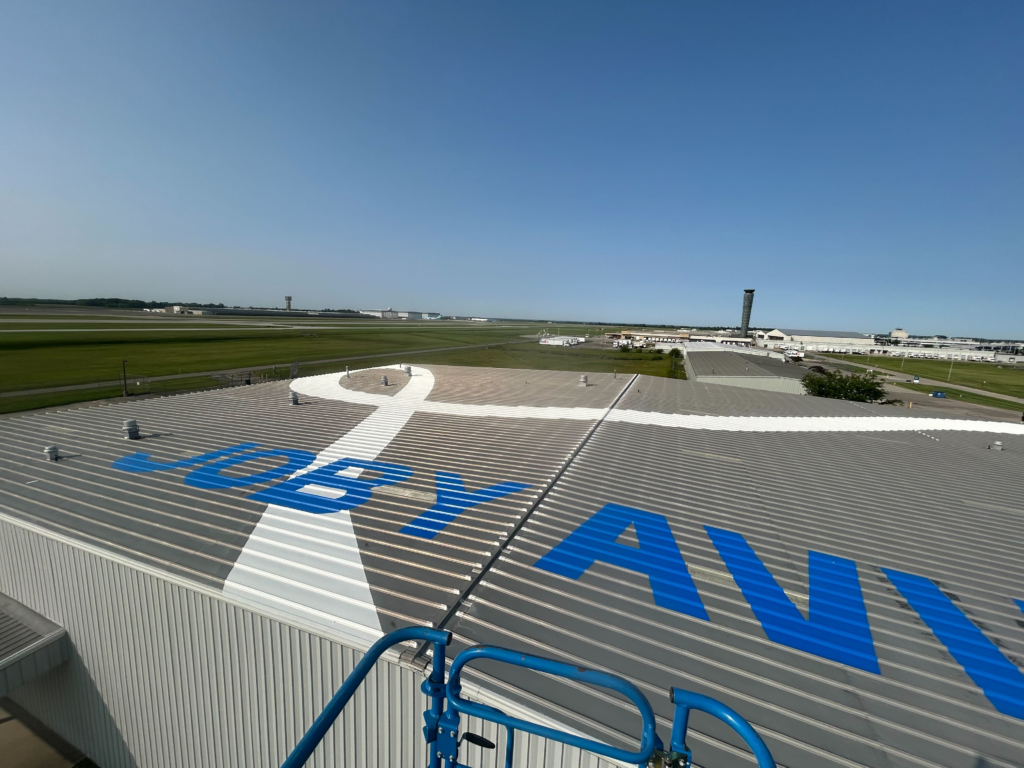

We’re proud to share the successful completion of Phase II of Joby Aviation’s facility renovation located near the Dayton International Airport, this adaptive reuse project transformed what was once a U.S. Postal Service mail sorting center into a vital hub supporting Joby’s growing aerospace manufacturing operations.

Building on the success of Phase I, Marker partnered with Joby to deliver Phase II under budget and ahead of schedule. This phase focused on modifications to support rotor manufacturing and testing, including the installation of a new clean room, upgraded lighting and ceiling systems, and other general building improvements. The open layout was constructed to meet current operational needs while maintaining flexibility for future production expansion.

The renovation posed unique challenges due to the state of the facility and the client’s shifting requirements. As Joby began defining how its specialized equipment would fit within the space, design changes were frequent. Marker’s team, led by Superintendent DJ Elleman, was extremely adaptable to any and all changes, adapted, developing the most efficient sequences possible for demolition and reconstruction to keep progress moving. One particularly complex task involved removing a suspended “catwalk” structure once used for mailroom security in the original building, which required meticulous planning and precision to complete safely and efficiently.

This partnership reflects Marker’s commitment to the core values “getting it done” and “getting it right.” Joby’s team noted their satisfaction with the process and indicated enthusiasm for continuing to collaborate on future facility improvements as their operations expand, expressing appreciation for Marker’s adaptability and responsiveness throughout both project phases.

Thanks to the project team: Derek Gesler, DJ Elleman, Mark Sullivan, Zach Stewart, Charlotte Levy, and everyone behind the scenes for making this project a great success.

Facility Features

- 30,000 SF

- Continuation of Phase I

- Delivered on budget and ahead of schedule

- Renovation

- Self-performance of demolition and ceiling installation

- Modifications put in place to support rotor manufacturing and testing